Application Case of Explosion-proof Zirconia Oxygen Analyzer in Chongqing Iron and Steel Rolling Mill

Release time: 2023-04-02

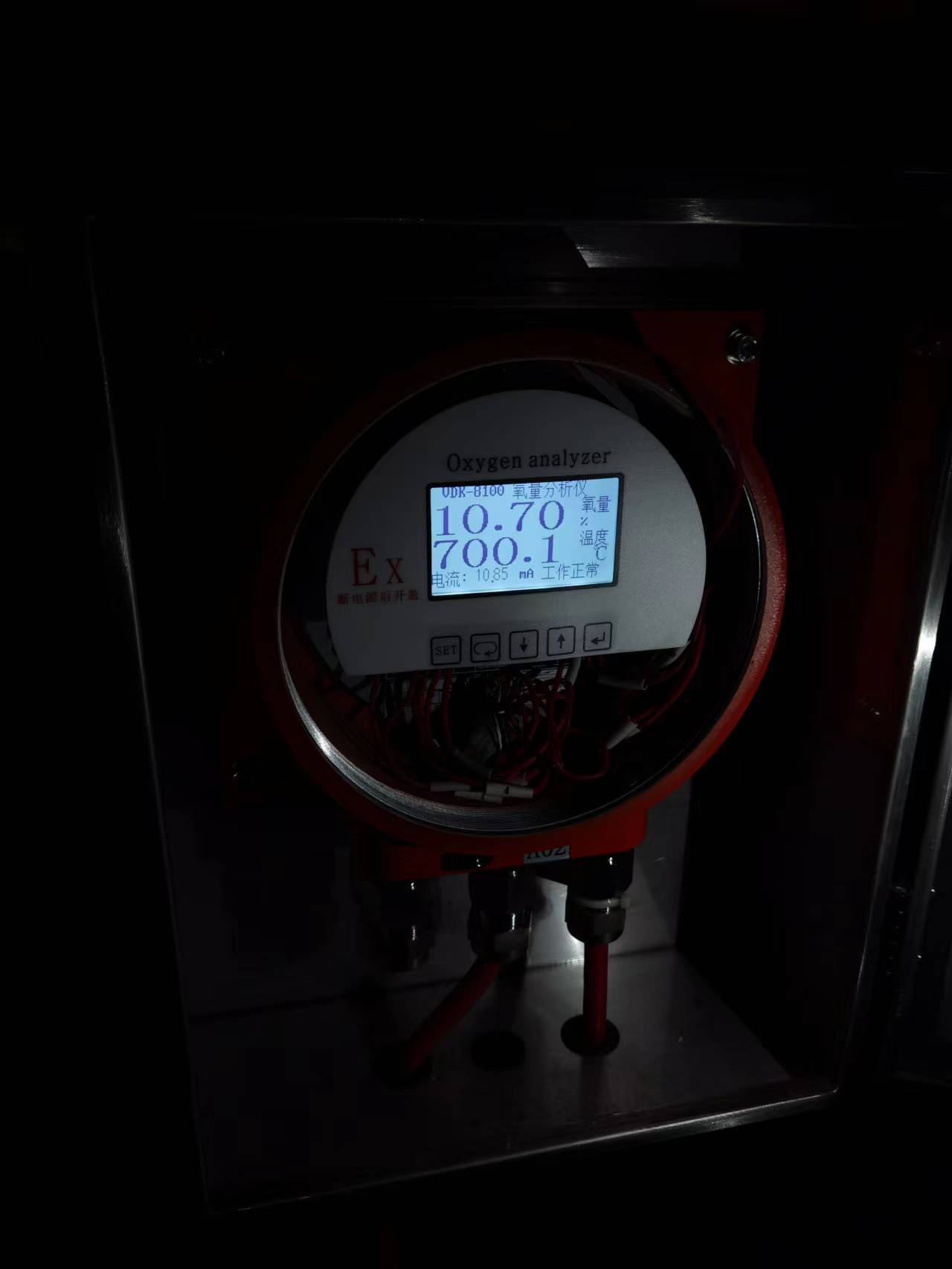

A case study of Chongqing Iron and Steel Group's rolling mill using our company's TFEX-8 explosion-proof zirconia oxygen analyzer. Used to measure the residual oxygen concentration in the flue gas of the rolling heating furnace. Our professional technicians installed and debugged on-site. Data access to the DCS system displays data results normally, accurately, and in real time. Operation is normal. Won the recognition of the customer's instrument and technology engineers.

Product Description:

The TFEX-8 explosion-proof zirconia oxygen analyzer is an intelligent oxygen content analyzer developed by our company. It features high sensitivity, good reproducibility and stability, wide range, automatic switching, fast response, and continuous online measurement. It can be used with various electric unit instruments, conventional display recorders, and DCS distributed control systems. It can quickly and accurately perform online display, detection, and analysis of the oxygen content of flue gas generated during the combustion process of boilers, kilns, and heating furnaces to achieve low-oxygen combustion control, achieving energy saving and consumption reduction, reducing operating costs, and reducing environmental pollution. It can be widely used in the iron and steel metallurgy, thermal power, electric power, petroleum, chemical, glass, building materials, magnetic materials, and oxygen production industries. It is an ideal equipment for process control and product testing.

Working Principle :

The zirconia oxygen analyzer uses the electromotive force of the oxygen concentration difference, which is converted by the detection instrument into a standard voltage signal linearly related to the oxygen content of the gas to be measured. It is input to the digital instrument input terminal, converted by A/D to the instrument's CPU, and after calculation, one path is sent to the instrument to display the oxygen content, and one path is sent to the instrument to display the temperature value, and the corresponding pulse control signal is output to control the temperature value. At the same time, the oxygen content is converted into a 4-20mA analog signal for transmission output, which is used for other control systems. The instrument has oxygen content and temperature alarm indications and is equipped with an external alarm relay. The instrument uses a reliable switching power supply, three-wire Pt1000 cold-end compensation, low-drift operational amplifier, high-resolution A/D conversion, LCD display, true PID temperature self-tuning control, and a 4-20mA+HART or 485 communication interface.

Features:

1. The TFEX-8 explosion-proof zirconia oxygen analyzer consists of two parts: a zirconia probe and an oxygen transmitter.

2. The explosion-proof zirconia probe uses corrosion-resistant alloy materials. The zirconia is easy to disassemble and replace, and no additional air pump is required. The reference gas is self-circulating, and a standard gas interface is provided for background and preset standard gas testing. A protective sheath can also be added according to user needs.

3. The explosion-proof zirconia analyzer instrument software is complete in function, all panel operation, simple wiring, integrated circuit, reliable performance, easy debugging, and the instrument performance is far ahead of its peers in China.

Technical Parameters:

1. Explosion-proof zirconia oxygen analyzer range: 0~25%O2

2. Zirconia analyzer instrument accuracy: ≤0.5%F.S

3. Zirconia analyzer operating temperature range: 0~1300℃

4. Zirconia analyzer measurement temperature: 0~600℃ (low temperature type), 0~800℃ (medium temperature type), 0~1300℃ (high temperature type)

5. Zirconia oxygen analyzer background correction: -20mV~+20mV

6. Explosion-proof zirconia oxygen analyzer output signal: 4-20mADC or 1-5V

7. Environmental conditions: 0~50℃, relative humidity < 90%

8. Power supply: 220VAC 50Hz

9. Detector heating furnace heating time: about 20min

10. Heating temperature: PID self-tuning control ≤±1℃ (constant temperature point arbitrarily set)

11. Response time: about 3S (90% response)

12. Display form: LED four-digit high-definition digital display, LCD display

13. Communication interface: RS232 or RS485

Installation Method:

1. Selection of installation point The flue gas temperature at the installation point should meet the relevant requirements. Generally speaking, the lower the flue gas temperature, the longer the service life of the detector, and the higher the flue gas temperature, the shorter the service life. The detector cannot be installed in a dead corner where the flue gas does not flow, nor can it be installed in a place where the flue gas flows very fast (such as the expansion cavity of some bypass gas ducts). In addition, it requires that the flue gas leakage is small, and the detector is easy to install and maintain. For medium and small boilers, it is recommended to install it before the economizer and after the superheater, because the flow direction of the boiler system flue gas is from the furnace to the steam drum, passing through the superheater, economizer, and air preheater, and then discharged from the chimney after being recovered and processed by the induced draft fan. If the measuring point is too close to the furnace outlet, due to the high temperature and fast flow rate, it will cause scouring corrosion of the stainless steel shell of the detector, shortening its service life; if the measuring point is too far behind, due to the leakage phenomenon in the flue system, the oxygen content at the measuring point will be higher, which cannot accurately reflect the oxygen content of the flue gas in the furnace.

2. Detector fixing flange on the furnace wall or flue A transition frame made of steel is used. The flange of the transition frame can be directly welded to the furnace wall or embedded in the furnace wall, but it must be airtight and firm. The flange at the other end of the transition frame is designed to fix the detector, so it must match the screw holes of the detector fixing flange. If a 12mm installation hole is selected, four 12mm installation holes are evenly distributed on the ¢130mm circle of the transition frame flange, and four M1O×40 screws are used to fasten it to the fixing flange of the detector. To prevent leakage, a rubber gasket can be filled between the two flanges.

3. Installation of the detector The reference gas of the detector is provided by natural air convection, and the detector needs to be installed horizontally, with the reference gas and standard gas interfaces facing down. Rubber gaskets must be filled between the detector installation flange and the transition frame flange to prevent air from leaking into the flue, affecting the measurement accuracy. The detector end must be more than 150mm away from the inner wall of the boiler, so that the exposed part of the porous ceramic of the filter faces away from the flue gas flow (the filter direction can be rotated separately) to avoid the ceramic body from being scoured by the gas and prolong its service life. When pushing the detector into the hot flue, in order to prevent the zirconium tube from bursting, it is advisable to push it in gradually in sections, generally at 10~20 centimeters/minute.

There are a total of six wires connecting the sensor to the secondary instrument or transducer, including zirconia, thermocouple, and heating furnace. 0.75mm2 plastic insulated wires can be used.