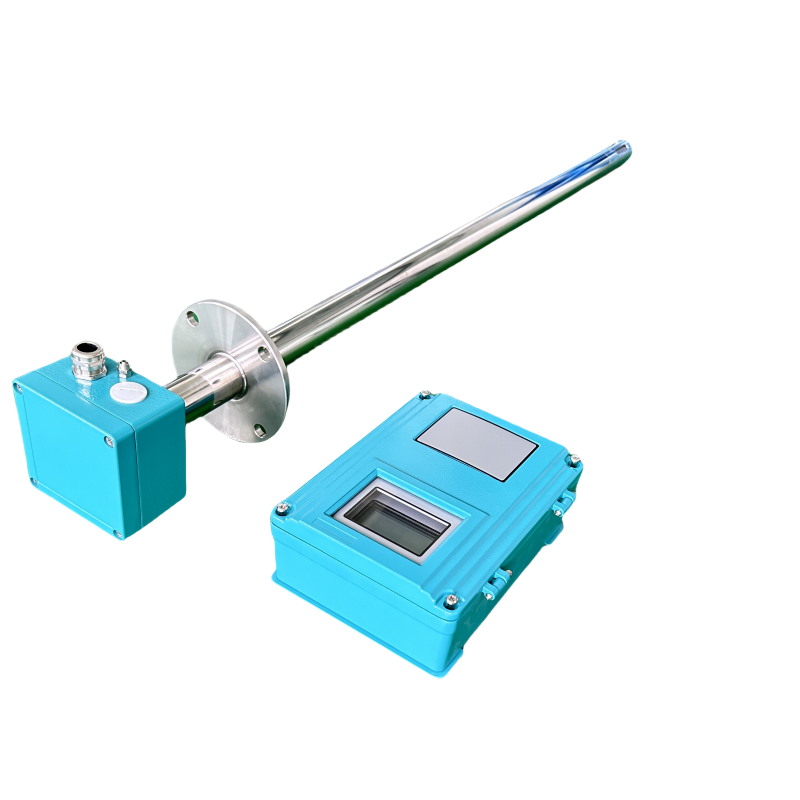

Zirconia oxygen analyzer

Keywords: R&D tuning fork densimeter, zirconia oxygen analyzer

Category:

Product Details

In industrial boiler combustion, variations in oxygen concentration affect fuel combustion efficiency. Accurate oxygen concentration data determines fuel utilization and energy-saving environmental protection effects. Furthermore, flue gas oxygen content is a particularly important economic operation assessment indicator in boiler air pollutant monitoring; its oxygen content value is the key basis for determining whether pollutant emission concentrations meet standards. Flue gas oxygen content control is a comprehensive and systematic issue.

In actual boiler operation, enterprises choose to install zirconia oxygen analyzers to monitor oxygen concentration in flue gas, providing a quantifiable reference basis for operation management. This analyzer uses imported chips and sensors, featuring high measurement accuracy, fast response speed, long service life, maintenance-free operation, corrosion resistance, wear resistance, resistance to cold and hot shock, and a simple structure. It is specifically used to measure the oxygen content in flue gas discharged during or after combustion in boilers, furnaces, kilns, dryers, and various combustion processes, serving as an important means of optimizing combustion and improving combustion efficiency. Simultaneously, the system's sealing must be ensured, and operation management strengthened, so that factors affecting flue gas oxygen content can be controlled, and pollutant emission concentrations can be controlled according to national standards.

As shown above, for boiler combustion processes, stable and reliable oxygen content data is essential. The zirconia analyzer used by the enterprise can promptly understand the oxygen content in the process. Based on the measurement data from the zirconia analyzer, strictly controlling the air-fuel ratio allows for complete fuel combustion, reducing exhaust heat loss, improving boiler thermal efficiency, and effectively controlling the emission of boiler air pollutants, playing a positive role in protecting and improving ambient air quality.

Anhui Tianfen Instrument Co., Ltd., manufacturer of zirconia analyzers, steel plant zirconia analyzers, chemical plant zirconia analyzers, zirconia analyzer manufacturers, power plant zirconia probes, garbage power plant zirconia analyzers, power plant zirconia analyzers, TKFX-ZOA zirconia analyzers, ZO-2000 desktop zirconia analyzers, MKFB-400-A/H explosion-proof zirconia analyzers, ZOA-300B zirconia analyzers, ZO-FIIB explosion-proof zirconia oxygen analyzers, CY-ZC, CY-ZDA zirconia analyzers, OXT3000 series zirconia oxygen content analyzers, integrated oxygen analyzers, corrosion-resistant zirconia analyzers, YB-88G zirconia oxygen analyzers, OXT1000 series zirconia analyzers, TKZO-5 zirconia analyzers, NFZRO2-5 zirconia analyzers, ZR402G zirconia oxygen analyzers, CE-2C, CE-2D zirconia analyzers, ZFK8R zirconia analyzers, steel plant hot blast stove zirconia analyzers, hazardous waste zirconia analyzers, MK-400-A-FHC corrosion-resistant zirconia analyzers, erosion-resistant zirconia analyzers, EXFZZRO2-88 explosion-proof zirconia analyzers, FZZRO2-5 zirconia oxygen analyzers, NFZO-05 high-temperature suction zirconia analyzers, YB-88GJ-ZW zirconia analyzers, wear-resistant zirconia analyzers, oxygen analyzers, trace oxygen analysis, steel plant zirconia analyzers, waterproof zirconia analyzers. Oxygen analyzers include the OAM-800 oxygen analyzer (zirconia) and the OAM-802 explosion-proof oxygen analyzer (zirconia). And the BOA-807 series (integrated) and BOA-807-R (split) series specifically for garbage power plant boilers. An oxygen analyzer is an instrument for measuring the oxygen concentration in flue gas and other non-combustible gases during combustion. Tianfen oxygen analyzers include the OAM-800 oxygen analyzer (zirconia) and the OAM-802 explosion-proof oxygen analyzer (zirconia).

Standard oxygen analyzers include the integrated OAM-800 and the split OAM-800-R. Using a direct plug-in online measurement method, it can display measurement data and fault information on-site, with high accuracy, fast measurement, and low maintenance. The OAM-800 series features a nano-coated zirconia sensor and various wear-resistant protective tubes.

Explosion-proof oxygen analyzers include the integrated OAM-802 and the split OAM-802-R. It is a flameproof product certified by PCEC. Suitable for various explosion-proof occasions such as boilers, heating furnaces, incinerators, and converters.

6000 series - Zirconia oxygen analyzer Zirconia probe TES300E Oxygen transmitter OCM6E

Explosion-proof grade: Ex d IIC T4 Gb

Probe material: 316L

Flue gas temperature: ≤700℃ (with high-temperature cooling drain pipe, it can reach 1500℃)

Protection grade: IP66

Flue gas pressure: -10~+10KPa

Flue gas flow rate: 0~50m/s

Ambient temperature: -40℃~+80℃

Response time: ≤0.5s

90% process time (T90 time): ≤5S

Insertion depth: 320mm, 535mm, 795mm, 1080mm, 1530mm, 1915mm

Measurement accuracy: ± 1% of the range or ± 0.1% of the reading O2

Housing: Die-cast aluminum housing with display

Explosion-proof grade: Ex d ib IIC T6 Gb

Dimensions: Ф230mm, height 143mm

Weight: Approximately 6kg

Power supply: 100~240VAC/50~60Hz

Power consumption: Maximum 200VA when heating, 100VA during normal operation

Ambient temperature: -40℃~55℃

Relative humidity: ≤97% (at 55℃)

Signal output: 4-20mA

Maximum load: ≤500Ω

Display: 192*64 graphic dot matrix LCD, Chinese and English menu

Protection grade: IP66

Option: Fully automatic calibration (purge) device