Online tuning fork densimeter/alcoholmeter

Keywords: R&D tuning fork densimeter, zirconia oxygen analyzer

Category:

Product Details

DMC Parameter Table for Series Tuning Fork Density Meter

Item | Fill in Specific Parameters | Notes | Attachment |

Name of Medium to be Measured |

|

|

|

Medium State |

| Liquid | |

| Solid-Liquid Mixture | ||

Medium Temperature Range |

| ℃ | |

Medium Density Range |

| Minimum Density (g/cm³) | |

| Normal Working Density (g/cm³) | ||

| Maximum Density (g/cm³) | ||

Medium Viscosity Range |

| mPa ·s | |

| cP | ||

Concentration Range |

| Volume Percentage Concentration | |

| Mass Percentage Concentration | ||

Operating Pressure |

| Mpa | |

Measurement Accuracy |

| General Purpose ±0.002 g/cm³ | |

| High Precision ±0.001 g/cm³ | ||

| Ultra-Precision ±0.0001 g/cm³ (Custom-made) | ||

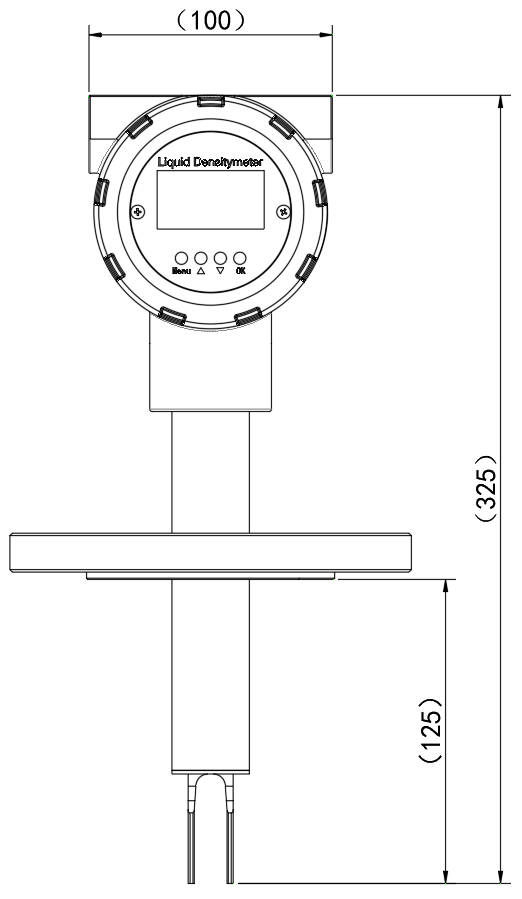

Insertion Length |

| 125mm (Standard) | |

| Other Customization | ||

Sensor Material |

| SUS 316L | |

| Hastelloy C22 | ||

| Other Customization | ||

Sensor Coating |

| Standard (Uncoated) | |

| Electropolished | ||

| PTFE Coating | ||

| Other Customization | ||

Power Supply |

| 24V DC (Standard) | |

| Other Customization | ||

Signal Output |

| 4-20mA RS485 (Standard) | |

Installation Method |

| Other Customization | |

| Sanitary Clamp | ||

| Flange | ||

| Other Customization | ||

Installation Kit |

| 3" (Φ76) Pipe + Sanitary Clamp (Standard) | |

| 3" (Φ76) Pipe + Flange (Standard) | ||

| Other Customization | ||

Other Supplementary Requirements:

| |||

Measurement Range | 0 — 2 g/cm³ (0—2000 kg/m³) |

Calibration Range | 0.6 — 1.25 g/cm³ (600 — 1250 kg/m3) |

Measurement Accuracy | ±0.001 g/cm ³ (±1 kg/m3) The stated accuracy applies to the calibration range of 0.6—1.2 g/cm³ (600 kg/m³—1250 kg/m³) |

Repeatability | ± 0.0002 g/cm ³ (± 0.1 kg/m3) |

Effect of Medium Viscosity | 0–50 cP Unaffected ±0.004 g/cm ³(±4 kg/m³) for the 50-200 cP range |

Operating Temperature Range | -10 ℃ — +120℃ |

Maximum Operating Pressure | 207 bar (3000 psi) |

Fluid Viscosity Range | 0 — 20000 cP |

Process Temperature Influence (After Calibration) | 0.0001 g/cm ³/℃ (0.1 kg/m3/℃) |

Process Pressure Influence | Negligible |

Built-in Temperature Sensor | PT100 BS1904 B Class, DIN 43760 B Class |

Wetted Material | Stainless Steel, Hastelloy C22, Monel 400 |

Fork Coating | Standard, PTFE or Electropolished |

Power Supply | 20 — 28V DC,35 — 45 mA |

Analog Signal Output | 4 — 20 mA, Isolated, Non-Self-Powered |

Output Accuracy (20oC) | ± 0.1% or ± 0.05% FS of Reading |

Output repeatability (-40 ~ +85oC) | ± 0.05% FS |

RS485 Communication | 9600 Baud rate, MODBUS |

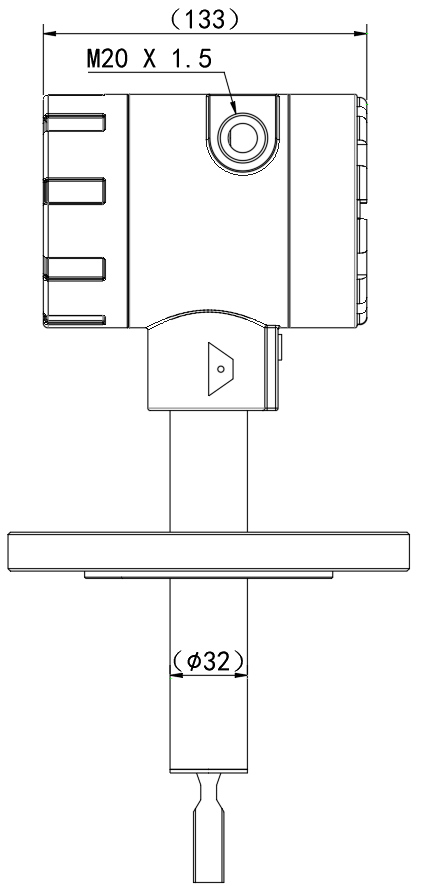

Process connection | Flange type, sanitary type, threaded type (customizable) |

Protection class | IP65 |

Housing | Aluminum alloy |

Explosion-proof certification | Exd IIC T6 Gb |

Weight | kg |