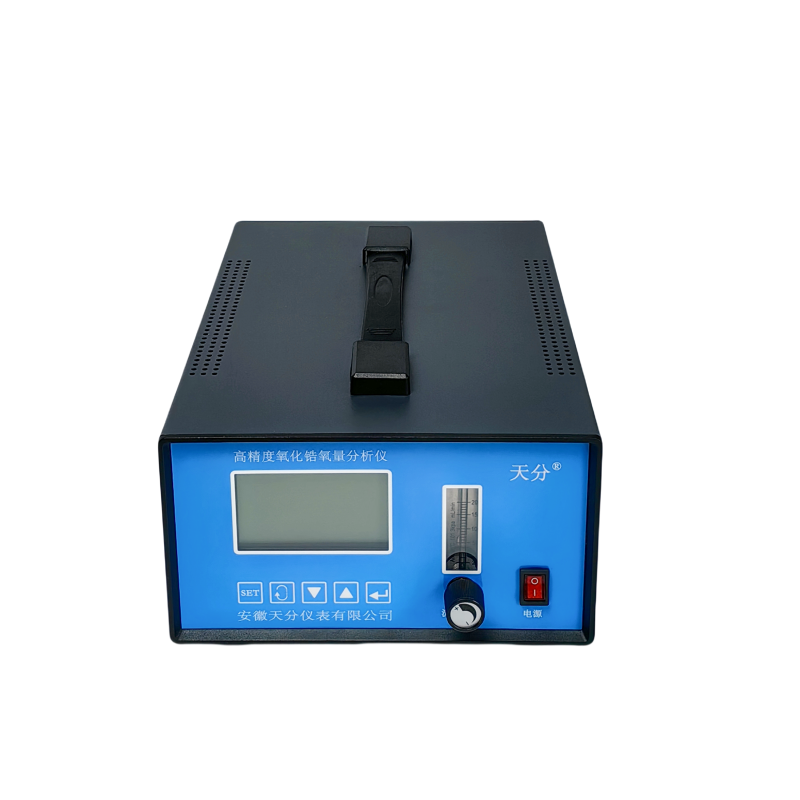

Trace Oxygen Analyzer Zirconia Analyzer

Keywords: R&D tuning fork densimeter, zirconia oxygen analyzer

Category:

Product Details

I. Introduction to the Core Working Principle

Simply put, the core of a zirconia sensor is a component that operates at high temperatures—typically 650°C - 750°C ) can become an oxygen-ion conductor as zirconia ceramic tubes. Platinum electrodes are coated on both the inner and outer surfaces of the tube. When the oxygen concentrations on the two sides differ, an electromotive force—corresponding to the concentration difference (measured as a millivolt signal)—is generated. This electromotive force is then measured, and the result is compared against a known reference gas (typically air, which has a lower oxygen content). 20.6% ) concentration, allowing for the precise calculation of the oxygen content in the gas being measured.

II. Main Technical Parameters

When selecting and using a zirconia oxygen analyzer, the following parameters should be given primary attention:

III. Main Application Scenarios

Zirconia oxygen analyzers have extremely wide-ranging applications, primarily focusing on areas where precise oxygen measurement is essential. Monitoring and controlling oxygen concentration In areas aimed at ensuring safety, enhancing efficiency, and improving product quality.

1. Air Separation and Inert Gas Industry

This is the most classic application area for zirconia analyzers.

- Nitrogen Purity Analysis : In nitrogen generation equipment PSA , membrane separation) export, monitoring the residual oxygen content in nitrogen to ensure nitrogen purity (e.g., 99.9% 、 99.99% And so on.

- Inert gases such as argon and helium : Monitor trace amounts of oxygen impurities during production and high-purity gas cylinder filling processes.

- Air Separation Tower : Monitoring the oxygen content in specific flow paths within the distillation column.

2. Metallurgical Industry

- Heat Treatment Furnace : During processes such as annealing, quenching, and tempering, nitrogen-hydrogen mixed gas is introduced HNX ) Form a protective atmosphere, monitor and control the oxygen content inside the furnace to prevent oxidation of metal workpieces at high temperatures, ensuring the smoothness of the product surface.

- Sintering Furnace In the field of powder metallurgy, controlling the oxygen content of the furnace atmosphere is crucial.

3. Chemical Engineering and Petrochemicals

- Cracking gases such as ethylene and propylene During the separation process, monitor the oxygen content to prevent catalyst poisoning and the risk of explosion.

- Synthetic Ammonia : Monitor the oxygen content in the feed gas.

- Polyolefin Process : Monitor trace oxygen in the reactor feed gas to protect the high-efficiency catalyst.

- Tank Inerting Protection : Inflating flammable and explosive liquid storage tanks with nitrogen while monitoring their oxygen content to keep it below the safety limit (typically lower than the critical oxygen concentration). LOC , such as 8% ) Below, prevent fires and explosions.

4. Electronic Industry

- Semiconductor Manufacturing : In crystal growth, oxidation, diffusion, CVD In these processes, ultra-high-purity protective gases (such as high-purity nitrogen and argon) are required, making it crucial to monitor their trace oxygen content.

- Electronic Component Packaging : Encapsulate under a protective atmosphere to prevent oxidation.

5. Electric Power Industry

- Boiler Combustion Optimization : Measuring the oxygen content in flue gas (constant oxygen levels, such as 0-10% ), by using feedback control to adjust the air supply, ensuring combustion occurs at the optimal air-fuel ratio, thereby enhancing boiler efficiency, saving fuel, and reducing nitrogen oxides ( NOx ) Emissions. This is one of the most widely applied scenarios.

6. Other applications

- Food and Pharmaceutical : On the packaging line, nitrogen gas is injected into the package (nitrogen-flushing for freshness), and its oxygen content is monitored to extend the shelf life of the food. / Drug expiration date.

- Scientific research Various laboratory reaction systems and tubular furnaces that require controlled or monitored atmospheres.

IV. Selection and Usage Considerations

- Gas Compatibility : Zirconia sensors for Reducing gas (For example, H ₂ , CO, CH ₄ ) and Corrosive gas (For example, HCl, SO ₂ , Cl ₂ ) Very sensitive. These gases can react with the reference-side oxygen or platinum electrode, leading to inaccurate measurements or damage to the sensor. When selecting, it’s essential to confirm the gas components being measured.

- Sampling System : For materials containing dust, moisture, and oil “ Dirty ” Gases must be equipped with an effective sample pre-treatment system (such as filters, coolers, dryers, etc.), or alternatively, a direct-insertion probe can be selected (which comes with its own built-in filter).

- Calibration : The instrument needs to be regularly calibrated using standard gases to ensure measurement accuracy. Typically, “ Zero gas ” (High-purity nitrogen, oxygen content below <1ppm ) and “ Measurement Range Gas ” (For example, 100ppm Or 1% O ₂ The nitrogen mixed gas).

In summary, the zirconia-based trace oxygen analyzer is an efficient and reliable online oxygen analysis tool, with its core value lying in providing precise data support for atmosphere control and safety assurance in industrial production processes.