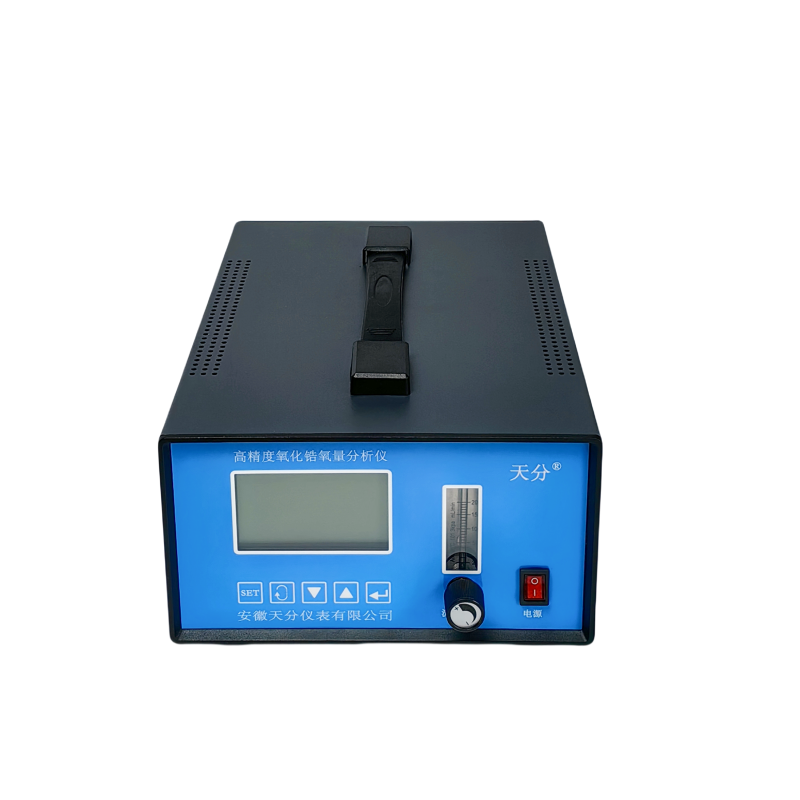

Portable trace oxygen analyzer, benchtop trace oxygen analyzer

Portable trace oxygen analyzer, desktop trace oxygen analyzer, oxygen analyzer

Keywords: R&D tuning fork densimeter, zirconia oxygen analyzer

Category:

Product Details

The portable trace oxygen analyzer, thanks to its flexibility, is widely used in various scenarios requiring on-site or mobile detection of trace oxygen concentrations.

- Industrial Gas Production and Purity Testing :

- Air separation for nitrogen and argon production : Monitor the oxygen content impurities in high-purity inert gases such as nitrogen and argon to ensure gas purity.

- Electronic Specialty Gases In semiconductor manufacturing, detecting trace amounts of oxygen in specialty gases—such as high-purity helium, hydrogen, and hydrocarbons—is crucial to prevent oxidation during the chip production process.

- Chemical Process Monitoring the oxygen content of protective gases or feed gases in various chemical reactors.

- Air separation for nitrogen and argon production : Monitor the oxygen content impurities in high-purity inert gases such as nitrogen and argon to ensure gas purity.

- Metal Processing and High-Temperature Processes :

- Magnetic material sintering 、 Metal Heat Treatment : Monitor the oxygen content of the protective atmosphere inside the furnace (such as ammonia decomposition gas) to prevent product oxidation and ensure product quality.

- Brazing, Bright Annealing : Ensure an anaerobic or hypoxic environment to prevent oxidation and discoloration of metal surfaces.

- Magnetic material sintering 、 Metal Heat Treatment : Monitor the oxygen content of the protective atmosphere inside the furnace (such as ammonia decomposition gas) to prevent product oxidation and ensure product quality.

- Safety Protection and Leak Monitoring :

- At Chemical equipment maintenance and pipeline replacement During the process, detect flammable gases within the equipment (such as H ₂ 、 CH ₄ ) Control the oxygen content in the environment to keep it within safe limits, preventing explosion accidents.

- Detection Sealing performance of cryogenic equipment (such as liquid nitrogen and liquid argon storage tanks) An increase in trace oxygen levels may indicate a leak in the insulation layer or vacuum failure.

- At Chemical equipment maintenance and pipeline replacement During the process, detect flammable gases within the equipment (such as H ₂ 、 CH ₄ ) Control the oxygen content in the environment to keep it within safe limits, preventing explosion accidents.

- Emerging and Professional Fields :

- Food packaging : Detect the oxygen content of inert gases (such as nitrogen) filled inside the packaging to ensure optimal freshness preservation.

- Medical gases : Analyze the concentration of medical oxygen or mixed gases.

- Scientific research experiment : Providing a rapid oxygen concentration detection method for experiments requiring precise atmosphere control.

- Key Features :

- · It uses imported fuel cell-based trace oxygen detection elements, which feature long lifespan and rapid response speed.

- · Suitable for measuring trace amounts of oxygen in reducing gases such as nitrogen, hydrogen, and argon.

- · Utilizing a fully Chinese-language human-machine dialogue menu, the operation is intuitive and convenient.

- · It features a large-screen dot-matrix LCD display that can simultaneously show parameters such as oxygen level, date, and time.

- · The upper and lower alarm points can be set arbitrarily within the full measurement range.

- · Equipped with a paperless recorder function, it automatically charts the changes in oxygen concentration over time.

- · Output 0 ~ 10 Or 4 ~ 20mA Standard signal.

- · The standard RS232 The communication port can connect to a serial printer or enable two-way communication with a computer.

Technical Performance Metrics : - · Measurement range: 0 ~ 10ppm、0 ~ 100ppm、0 ~ 1000ppmO2

- · Measurement accuracy: > 10 ppm ± 3% FS 、 ≤10 ppm ±5% FS

- · Output: 0 ~ 10mA (0 ~ 1.6 kΩ) Or 4 ~ 20mA(0 ~ 800Ω)

- · Repetitiveness: ≤±2%FS

- · Power Consumption: ≤8W

- · Power supply: 220VAC ± 22VAC , 50Hz ±1Hz

- · Ambient temperature: 0 ~ 40℃

- · Sample gas flow rate: 300ml / min

- · Intake pressure: < 0.1Mpa ( 0.05MPa Best)

- · Intake air temperature: 0 ~ 40℃

- · Alarm contact capacity: 265VAC/1A

- · External dimensions: 198 × 138 × 250 mm

- · Instrument weight: 4.0kg

- Food packaging : Detect the oxygen content of inert gases (such as nitrogen) filled inside the packaging to ensure optimal freshness preservation.