Little knowledge about Zirconia Sensor

Release time: 2019-07-10

For boilers, the oxygen content of boiler flue gas is a very important parameter, as it is a key indicator for judging the combustion condition and efficiency of the boiler. Up to now, with the development of science and technology, the common method for measuring the oxygen content of flue gas in small and medium-sized boilers is to use a zirconia sensor. Many users lack professional understanding of the measurement principle and usage of zirconia sensors. Today, the technical engineers of Anhui Tianfen Instrument Co., Ltd. will provide a detailed explanation for zirconia users!

Analysis of the Measurement Principle of Zirconia Sensors

The basic principle of zirconia oxygen measurement is to utilize the so-called "oxygen concentration difference potential." Porous platinum electrodes are attached to both sides of a zirconia piece, and it is kept at a high temperature. If the oxygen content in the gas on both sides is different, oxygen ions will undergo "hole migration" on the electrodes. Because oxygen ions carry a divalent positive charge, an electromotive force will appear between the two electrodes. This electromotive force is generated due to the difference in oxygen concentration between the two sides of the solid electrolyte, and is called the oxygen concentration difference potential, which can be calculated by the Nernst equation:

E=RT/4F×ln(P''O2/P'O2)

Where R is the gas constant, T is the thermodynamic temperature (K) of the battery, F is the Faraday constant, and P''O2/P'O2 is the oxygen partial pressure on both sides of the electrode.

When one side of the solid dielectric is air, the electromotive force E output by the oxygen concentration difference battery can be used to calculate the oxygen partial pressure on the other side of the solid dielectric. Therefore, a reference air needs to be introduced when using the zirconia sensor. This is the measurement principle of the zirconia oxygen analyzer.

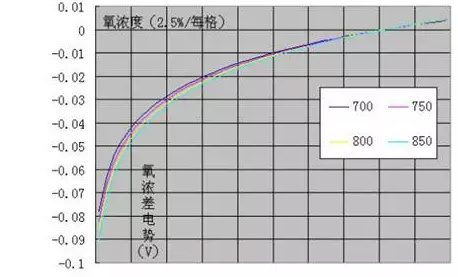

The curve relationship between oxygen concentration and oxygen concentration difference television:

Analysis of Precautions for the Use of Zirconia Sensors

1. Generally, zirconia sensors are divided into low-temperature and high-temperature types. We must remember not to mix them up. Generally, high-temperature sensors are required for boiler zirconia sensors.

2. Because the zirconia sensor uses precise electronic components inside, avoid installing it in places with severe vibrations during use.

3. Do not install the zirconia sensor in an overly humid environment, and keep it away from corrosive substances.

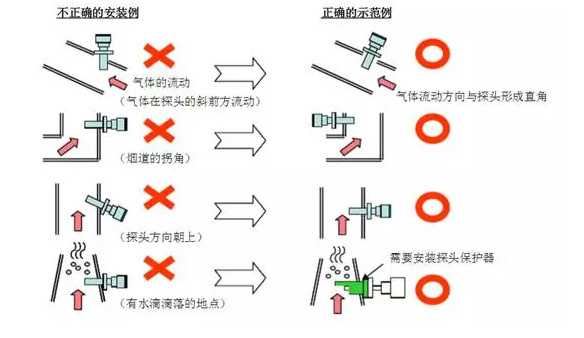

4. It should be installed in the correct position, as shown in the figure below (for reference only).

5. Zirconia sensor accuracy drift and calibration.

During use, there are many interfering factors, such as aging of the zirconia tube, ash accumulation, and corrosion of the electrodes by SO2 and SO3. After running for a period of time, the zirconia sensor will experience accuracy drift, resulting in measurement errors. This measurement error may cause incorrect judgment by operators or automatic control equipment, which is very dangerous.

Therefore, it is best to use zirconia sensors with self-checking functions, and the instrument must be calibrated regularly. The calibration cycle depends on the usage environment and conditions, generally around 1-3 months.

6. The working principle of the zirconia oxygen sensor requires a standard atmosphere as a reference gas. If there is no stable reference gas provided to the sensor, the detection accuracy will be greatly reduced. Therefore, during use, the normal input of the reference gas must be ensured.

However, because zirconia sensors are ceramic materials with complex forming processes and high technical requirements, it is still necessary to find professional zirconia manufacturers.

Another point worth noting is that the use and management of zirconia sensors are also very important, especially the self-checking function and timely calibration. If you purchase a sensor without a self-checking function and do not calibrate it in time, the accuracy will be greatly reduced.

Recommended product

EXNFZRO®2 Explosion-Proof Zirconia Oxygen Analyzer Zirconia Analyzer