How to correctly use and maintain a zirconia oxygen analyzer?

Release time: 2019-07-10

The zirconia oxygen analyzer is an indispensable instrument and equipment in the production operations of some industries today. It can accurately and quickly monitor and analyze the flue gas content produced during the combustion process of combustion equipment such as kilns, boilers, or heating furnaces, thereby ultimately achieving low-oxygen combustion control, saving energy, and greatly reducing environmental pollution.

Regarding the precautions for daily use and maintenance of the zirconia oxygen analyzer, the following points need our attention.

I. After using the zirconia oxygen analyzer, it is not recommended to calibrate immediately.

What is the reason for this? Because within 24 hours of a cold start, the indicated value is generally abnormal. The correct method is to use standard gas for calibration after one day of operation. What is the reason for this? This is because a cold detector or newly installed detector may contain adsorbed water and combustible substances. After heating up, as the temperature rises, these adsorbed water evaporates and combustible substances burn, consuming the reference air in the reference side battery, leading to the oxygen content in the reference air being lower than the normal value of 20.6%. This can cause the detector signal to be low, or even negative, directly resulting in a higher measured oxygen content value, even exceeding 20.6%. Therefore, the data measured at this time is not accurate.

Technical engineers point out that the correct selection method is to wait until the moisture and combustible substances inside the detector are completely replaced by fresh air before the measured data can be accurate. Therefore, technical engineers suggest: a zirconia detector should be heated up for at least one day before calibration. So, after using the zirconia oxygen analyzer, it is not recommended to calibrate immediately.

II. Calibrate the zirconia analyzer regularly.

Generally, there are many interference factors during the use of the zirconia oxygen analyzer, such as the aging of the zirconia tube, dust accumulation, and the corrosive effect of SO2 on the electrodes. These factors can cause the performance of the zirconia analyzer to gradually change after a period of operation, which directly leads to inaccurate data during our measurements. Therefore, technical engineers suggest that during the daily use and maintenance of the zirconia oxygen analyzer, we need to calibrate the instrument regularly. Typically, the calibration cycle is 1-3 months, but it also depends on the usage environment and conditions of the zirconia oxygen analyzer.

III. Do not easily switch the zirconia oxygen analyzer on and off.

During the use and maintenance of the zirconia analyzer, do not easily switch the instrument on and off. Firstly, because the zirconia tube is a ceramic tube, although it has certain thermal shock resistance, during the shutdown and startup process, sudden heating and cooling can lead to large temperature changes that may cause the zirconia tube to fracture. Therefore, we should minimize unnecessary switching operations.

Secondly, because the thermal expansion coefficients of the platinum electrode coated on the zirconia tube and the zirconia tube itself are inconsistent, after a period of use, detachment may easily occur during switching, causing the probe's internal resistance to increase, or even damaging the detector!

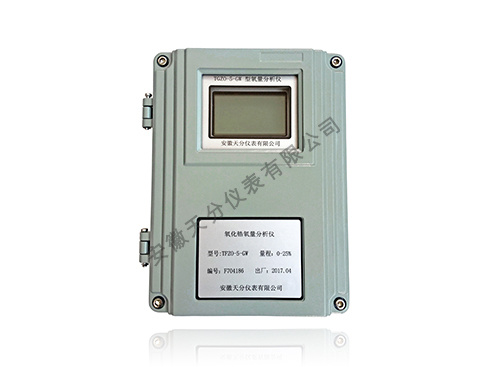

Recommended product

EXNFZRO®2 Explosion-Proof Zirconia Oxygen Analyzer Zirconia Analyzer